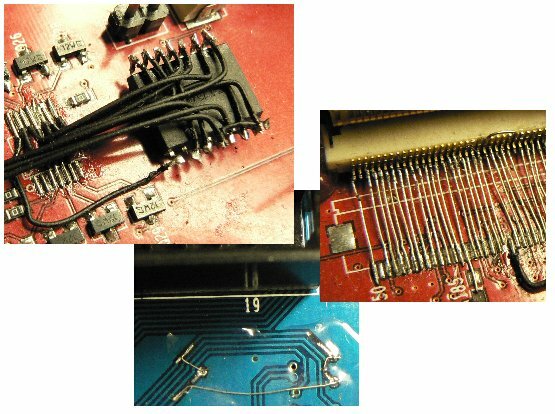

For designs to become reality, they need to go through the prototype stage. Very few designs of high complexity will work the first time, hindsight is normally 20:20. Since most of the work performed by us utilises high-density miniature components on multi-layer boards, we have developed techniques to rework boards in such a fashion that we can test our changes before producing the next revision. Prototype designs often include provision for modification and adjustment through resistor fitment options. If this is not the case then PCB tracks need to be cut and wires placed to rewire the tracks. These are normally kept as short as possible and fitted in such a way that no components are covered, allowing further rework to be carried out if required. Solder mask can be scratched off to allow connection to otherwise normally non-accessible areas of the board. Chip legs can be lifted without removal of the pa to allow reconnection of both pin and pad if required. In extreme cases (very rare) we have replaced components with different footprints and pin outs and got these working before using them in the next revision. As these required modifications are not known before going to manufacture, some demanding but interesting modifications have been made without any fear of harming the prototypes.